Image credit: Unsplash

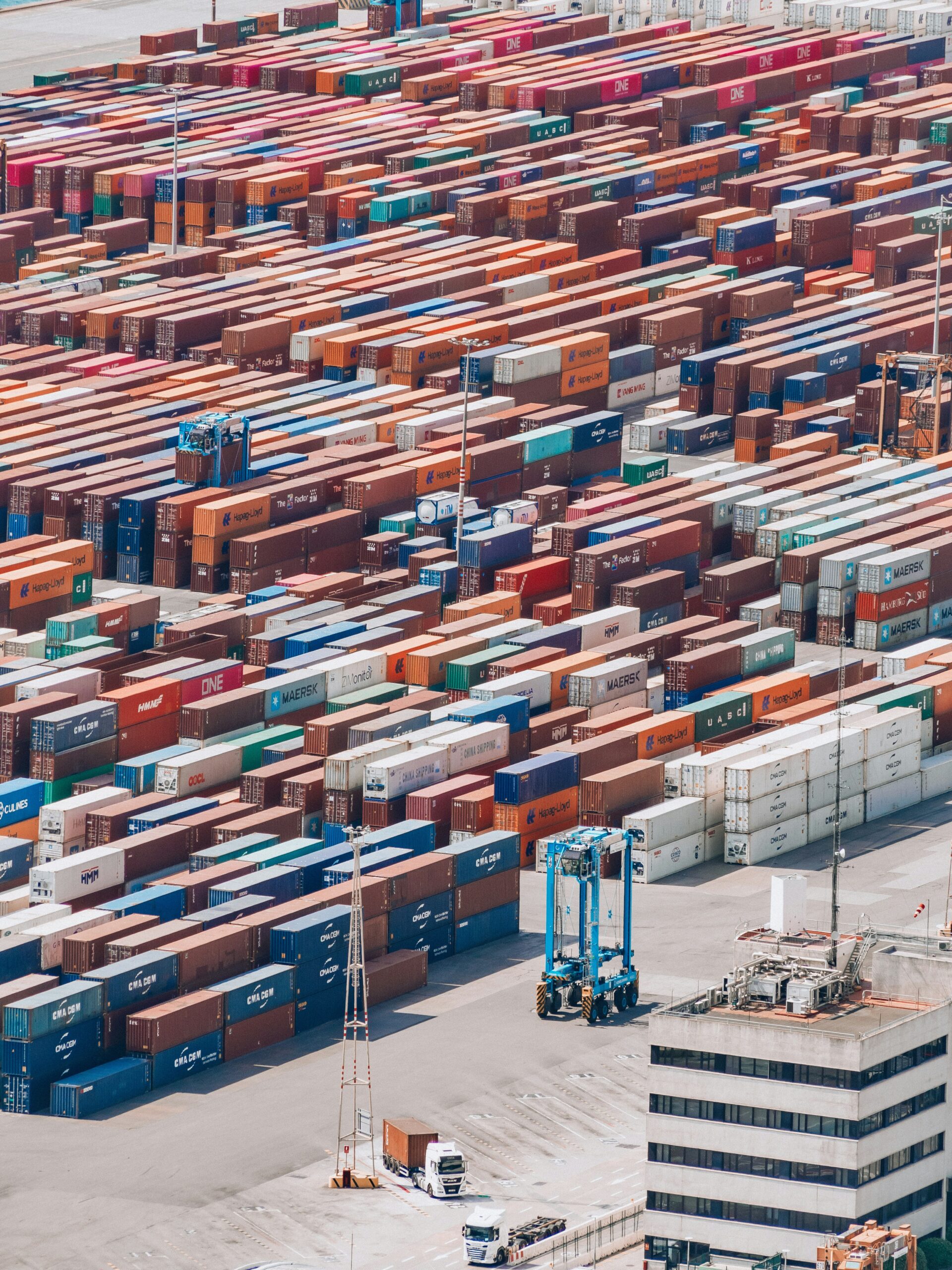

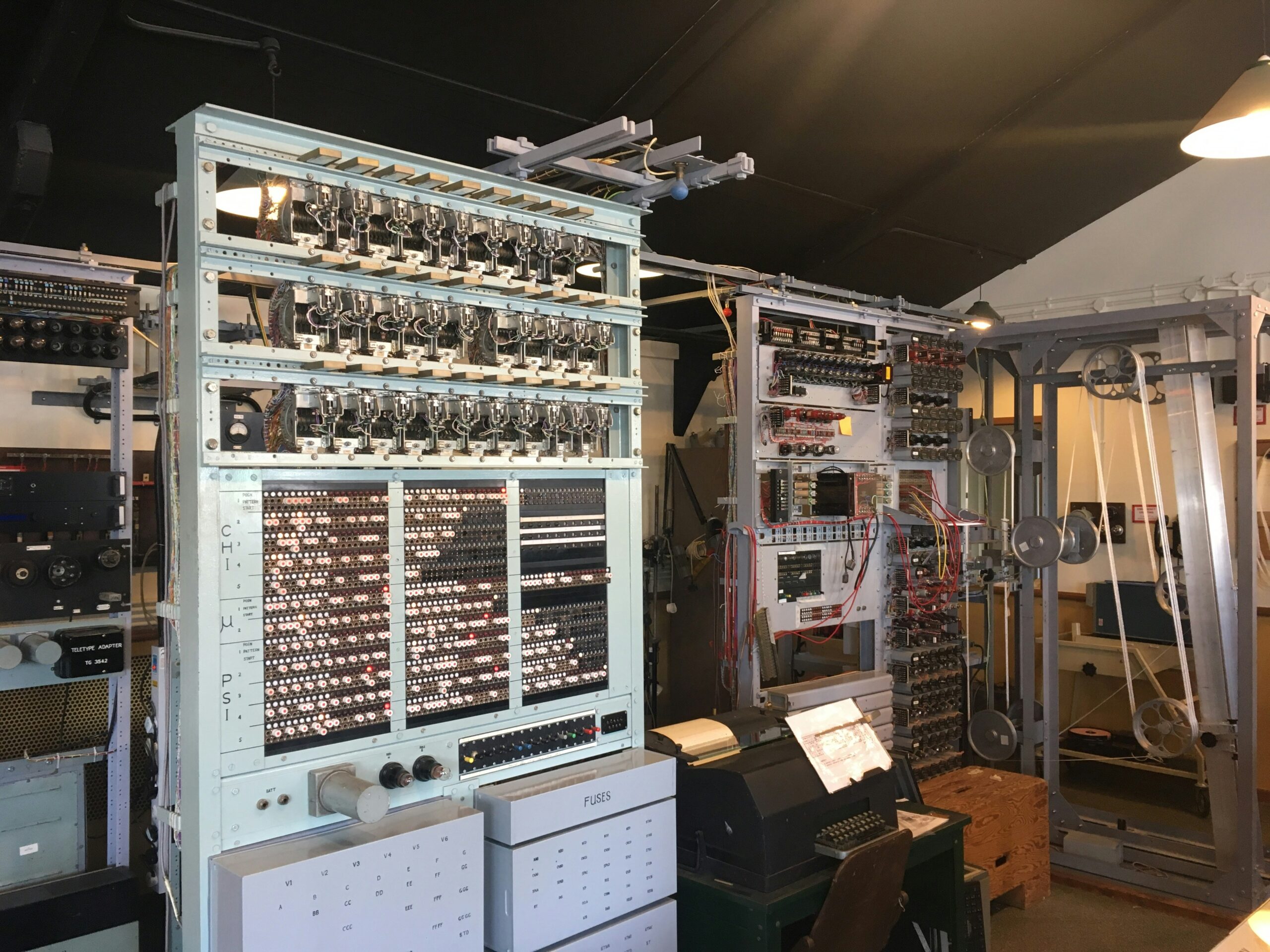

In today’s fast-paced logistics environment, effective inventory management is more than a back-office function—it is a competitive advantage. Mistakes like stockouts, delayed shipments, or data discrepancies can ripple across supply chains and cost companies millions. With rising e-commerce expectations, labor shortages, and increasingly complex operations, businesses are turning to artificial intelligence to modernize the warehouse. One company leading this transformation is Gather AI.

Rather than relying solely on manual checks or barcode scans, Gather AI applies artificial intelligence and autonomous data capture to provide a clearer, more actionable picture of what is happening inside a warehouse, pallet by pallet and aisle by aisle.

What Is Gather AI?

Gather AI is a vision-powered warehouse intelligence platform that digitizes inventory and material handling without disrupting existing workflows. It uses autonomous data capture through drones and vehicle-mounted cameras to scan inventory in warehouse environments and deliver real-time visibility into stock conditions.

The platform collects high-resolution visual data and applies AI models to extract insights that matter most to operations teams: What is in stock? Where are the inefficiencies? Which pallets are missing, misplaced, or blocked? The system works across a range of environments, including ambient, refrigerated, and freezer storage, where manual inventory checks are particularly costly and risky.

Why Inventory Systems Need an Overhaul

The rise of next-day delivery expectations, globalized fulfillment networks, and persistent labor gaps has revealed a critical truth: traditional inventory processes are no longer enough.

1. Accelerating Fulfillment Timelines

E-commerce growth has reshaped the warehouse. Meeting customer expectations for on-time, in-full (OTIF) delivery requires inventory systems that operate with speed and precision.

2. Labor Constraints

Warehouses worldwide are struggling to staff shifts. According to the U.S. Bureau of Labor Statistics, job openings in warehousing continue to outpace hires. In this climate, automation is not just a productivity booster; it is a business necessity.

3. Supply Chain Complexity

Modern supply chains span continents and include multiple handoffs. A single missed scan or data entry error can trigger costly disruptions downstream.

How Gather AI Supports Warehouse Optimization

Gather AI helps teams move from reactive inventory practices to proactive warehouse management. Here’s how:

Autonomous Data Collection

Drones and vehicle-mounted vision systems autonomously capture data as they move through the warehouse, scanning barcodes, text, and images without manual input. This reduces time spent on inventory tasks and helps teams focus on higher-value work.

AI-Driven Insights

Gather AI’s platform translates raw imagery into operational intelligence. It flags inventory that is missing, misplaced, or blocking access. Users receive reports that visualize problem areas and recommend next steps.

Continuous Visibility

Data is processed in the cloud and integrated into dashboards or warehouse systems, allowing teams to access real-time views of inventory health and storage conditions without waiting for a quarterly count or physical walk-through.

Scalable Across Sites

The system is designed to scale with growing operations. Whether managing one warehouse or an international network, businesses can deploy the same platform across sites with minimal configuration.

What Kind of Impact Can It Make?

Gather AI’s customers have reported measurable improvements in labor efficiency, inventory visibility, and OTIF performance. For example, one retailer using the platform saw a 30% reduction in inventory discrepancies within three months, resulting in fewer missed shipments and less time spent resolving errors.

Other common benefits include:

- Labor savings: Automating manual scans frees up workers for more complex tasks

- Faster inventory audits: What once took days can now take hours

- Improved customer service: Fewer surprises in stock levels mean fewer disruptions to orders

- Stronger compliance and reporting: Visual proof of inventory conditions enhances traceability and accountability

Important Considerations

Gather AI’s technology opens new possibilities for warehouse visibility, but implementation comes with considerations:

- Upfront Investment: Though the long-term savings may outweigh the costs, companies must account for onboarding, equipment, and training

- Warehouse Fit: Highly irregular layouts or tight, congested spaces may limit the effectiveness of autonomous equipment

- Data Security: As with any cloud-based platform, businesses must ensure proper cybersecurity protocols for handling operational data

- System Maintenance: Hardware and software require periodic updates, calibration, and monitoring

Who Benefits Most?

Gather AI is well suited for businesses that depend on consistent inventory availability and operate in high-throughput or high-risk environments. These include:

- Retailers and distributors with large SKU counts and seasonal demand swings

- 3PLs managing complex inventories across multiple customers

- Manufacturers with just-in-time or multi-stage production processes

- Cold storage operators aiming to minimize manual exposure to extreme temperatures

Building for the Future

One of Gather AI’s strategic advantages is its collaborative approach. The company partners with logistics providers, warehouse software platforms, and robotics companies to integrate seamlessly into broader operations. It has also received venture funding to support R&D and international expansion.

Looking ahead, Gather AI is investing in predictive analytics and deeper WMS integrations so warehouses not only see what is happening now but can also anticipate what is coming next.

A Glimpse at What’s Next

Automation will not fully replace human intuition in the warehouse, but it can augment it. As the logistics industry continues to digitize, companies that adopt AI-driven tools will be better positioned to adapt, scale, and serve their customers reliably.

Gather AI is part of this broader shift, bringing visibility, intelligence, and scalability to the heart of the supply chain. While the technology may not be a perfect fit for every warehouse, it represents a clear step forward for companies aiming to turn their warehouses into data-driven command centers.

Written in partnership with Tom White